NaturalSorb Air Filtration Products

NaturalSorb is a product designed for commercial kitchens and HVAC/R use that provides an eco-friendly and sustainable solution to air filtration needs.

They will keep metal filters and extract systems free of grease for long periods of time, even exceeding 2 to 3 years.The NaturalSorb product is not intended to replace the existing filters in your exhaust hood, (including the UL1046 compliant flame baffles), but rather to be used in conjunction with them.

The NaturalSorb product is also revolutionary in the marine industry, as it’s ability to immediately absorb fuel spills and maintain bilge system cleanliness is unrivaled - a critically important need when there is a fuel spill within the marina or yacht basin.

NATURALSORB GREASE FILTRATION- BACKGROUND and PERFORMANCE

Background

Each year, fires occur in commercial kitchens during cooking processes adjacent to air extract systems. When heat and flames are able to enter the extract hoods, the grease load in the duct beyond the hood is often heavy such that following ignition, the fire is able to spread rapidly and violently to remote and often inaccessible areas of the building. The cost to life and property is considerable despite the sophistication of known fire suppression systems.

A safe low cost and simple means to substantially reduce the grease load inside commercial kitchen extract systems would have considerable merit, especially if it could be easily retrofitted within existing kitchens.

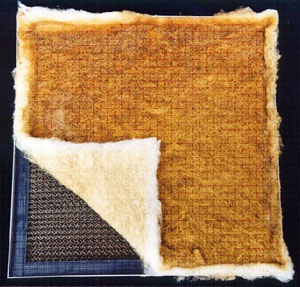

NATURALSORB Grease absorbers are a disposable filter media comprising a flexible open textured blanket made entirely from sheep wool fibre.

The fibrous blanket has been designed to harness the strong and unique attraction between grease and wool and create a filtration media to entrap and remove grease droplets from an air stream with quite superior effectiveness. Incorporated into the design are reliable visual indicators by which the user can judge when to replace the Grease Filter before the grease load exceeds certain deliberate limits.

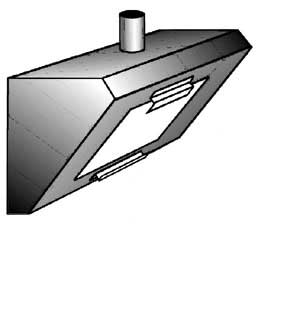

The product is an enhancement to existing listed filters commonly used within existing and new commercial kitchen air extraction systems. It is fixed across and adjacent to the upstream face of the listed filter and results in a dramatic reduction in the rate at which grease builds up on all surfaces and components within the interior of the extract system. Grease deposits on the roof and other exterior building surfaces simply ceases.

To provide the user with both convenience and safety, each Grease Filter is attached across the face of a light stainless steel rectangular frame within which is a support grid to hold the protector 1 ½ inches above the upstream face of the listed filter. The frame is then mounted and sealed to the face of the hood by means of simple brackets that have been riveted in place for this purpose. All air is then filtered twice before entering the hood. Whenever the absorber requires replacement, a special mounting tool with an extended handle enables the user to remove and return the frame to the hood without climbing off the kitchen floor.

Soiled Grease absorbers are held within a metal container with a securely fitting lid before disposal by incineration or placing in landfill via any general household or commercial garbage disposal system.

HOW GREASE ABSORBERS WORK:

Greasy vapours drawn through the Grease absorber naturally adhere to the wool fibres upon contact. The Grease absorber has been configured to provide just the right balance of dynamics to effectively deal with virtually all the airborne contaminants. Resistance to air flow is minimal, and during normal service, air flow is not noticeably affected, if at all.

As the incoming contaminants impinge the outer fibres of the Grease absorber, the collecting material naturally ‘wicks’ along the fibres and into the core of the Grease absorber, aided by the flow of passing air.

The contaminants adhering to the Grease absorber are stored along the wool fibres themselves, rather then within the spaces between the fibres. This prevents premature blocking.

As the wool fibres approach the limit of material that they can hold, the wicking activity reduces and small droplets of grease begin to form on the outer fibres of the face of the Grease absorber. Because of the natural oleophilic attraction between the grease and the wool fibres, the droplets are securely held and will not drip back unless quite extreme and obvious abuse of the system occurs.

The droplets are the prime visual indication that the Grease absorber will soon need to be replaced and warn that the air permeability is about to rapidly degrade as the spaces between the fibres blind over and grease collection ceases.

The degree of colour contrast between the surface of the Grease absorber and the greasy deposits further enables the user to reliably determine when to change the blanket.

SUMMARY OF PERFORMANCE BENEFITS:

- The metal filters remain dry

- The grease drainage channels in the hood remain dry

- For long periods, the plenum remains grease free and

- Virtually no grease accumulates in the ducting, on the roof or beyond

SPECIFICATIONS:

Grease Absorber

Open textured non woven wool absorber comprising a blend of Virgin and fine sheep wools evenly dispersed to create a homogenous non woven fibrous absorber of 5 -13mm loft and nominal dry weight of 60-145 gsm.

The structural integrity will be enhanced by the application of an environmentally friendly adhesive resin that is suitable for bedding infill, by means of spray bonding.

Antimicrobial treatment suited for bedding infill such as Ultra-fresh 300 DDN as required by the Supplier shall be applied 1% by volume to the fibres or at such other rates recommended by the manufacturer of such treatment.

The absorber may be installed in either orientation.

Packaging and Identification:

The product is compressed and vacuumed packed into 70 um plastic bags each containing 24 “Combo” blankets cut to size and available in a range of sizes to generally suite all standard listed filters.

A product bulletin is enclosed in each bag detailing storage instructions etc and identifying the Supplier and Master Distributor, the size of the blankets contained therein and also a batch number and other marks to provide traceability for QC purposes. The bulletin will provide means to display the ETL/UL evaluation report number when appropriate. Alternatively, the preceding information may all be printed or fixed on the exterior of the plastic bag.

PRODUCT DEVELOPMENT:

NATURALSORB grease absorbers have many years of development and use.

Research began to find methods to improve grease protection and simplify kitchen exhaust hood management issues. A number of avenues were explored before it was decided to develop a disposable media that would be used to provide additional grease filtration to existing extract systems.

After a range of materials had been tested, it was found that a filter absorber comprising mainly wool fibres could be refined to outperform all other options.

While the incredible results that we achieved during the trial period continued to exceed our expectations in the wider marketplace, it was some considerable time before it was clear that such grease protection would be achieved under all types of grease loading and food preparation.

CONSIDERATIONS

CERTIFICATIONS

In February of 2006, NATURALSORB received the coveted ETL certification from Intertek Testing Services, for its use and compliance under UL 1046, UL 710 and UL 300 Standards. This certification is recognized throughout the world.

Factory Inspections and general monitoring

ETL has and continues to make regular factory inspections to monitor quality as part of their certification requirements as well as the review of all NATURALSORB marketing and technical material.

Code compliance

NATURALSORB Grease Absorbers are a new and UNIQUE CLASS of kitchen exhaust hood grease protection and cannot be compared to existing exhaust hood maintenance technologies which largely comprise permanent re-usable metal filters, attended by constant cleaning and hygiene issues.

NATURALSORB Grease Absorbers offer;

- Supplementary grease protection.

- Disposability – requires no cleaning.

- Resistance to bacterial growth due to their being actively sanitised.

- Self limiting grease holding capacity engineered to remain within intentionally safe limits.

- Easy monitoring with NO risk of unsuspected grease build up.

- Environmental responsibility, and sustainability.

Existing standards (including National Fire Protection Agency Bulletin 96) had not anticipated the benefits to be gained by supplementary disposable grease protection. In the regulatory sense the NATURALSORB Grease Absorber system meets equivalency standards and far exceeds any current performance objectives concerning grease protection, fire safety and hygiene, as evidenced in our ETL certification.

When it is used in conjunction with a UL 1046 flame baffle, the NATURALSORB Grease Absorber System achieves the ultimate fire safety goals;

- Flames are restricted from entering the ducting .

- There is cost effective and unrivalled grease protection for both hood and ducting.

|

|